Check our passion on CNC Machining

Reliable CNC Machining delivers precision-engineered components for industries demanding uncompromising quality. Our reliable CNC machining services leverage advanced multi-axis machines and ISO 9001-certified processes to handle complex geometries in metals, plastics, and composites. From prototyping to high-volume production, we ensure ±0.005mm tolerances, strict material traceability, and on-time delivery—empowering aerospace, medical, and automotive innovators worldwide.

We specialize in delivering high-precision CNC machining services tailored to meet the unique needs of various industries, including aerospace, automotive, medical, and consumer electronics. Our state-of-the-art equipment and experienced team ensure that every component meets stringent quality standards.

CNC turning removes material by contacting a cutter with the high-speed rotating workpiece and is usually used to create round or tubular shapes. The CNC turning process allows the generation of complex external geometries and internal holes, including the machining of various threads..

CNC milling is a subtractive manufacturing method that uses a cutting tool to moves and rotate to remove material. CNC mills can be used for cutting and machining operations of various plastic and metal materials. It is suitable for any industry that requires precision components and is also an ideal tool for making molds.

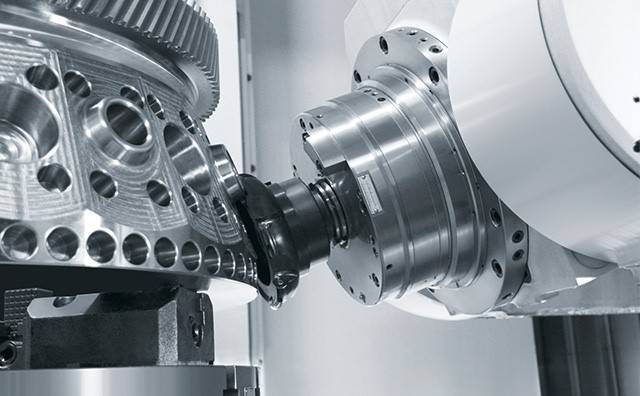

5-axis CNC machining allows complex parts with multiple side features to process up to five sides in a single setup. This can pay big dividends in better machine utilization, reduce setups and cycle times, and improve quality. The ability of 5-axis machining will make our CNC factory more cost-effective for a wider range of work.

The process typically starts with the creation of a 3D CAD model or 2D drawing of the part to be machined. This design serves as a blueprint for the CNC machine to follow.

Once the design is finalized, CAM (Computer-Aided Manufacturing) software is used to generate toolpaths based on the CAD model. This software translates the design into a series of instructions that the CNC machine can understand.

The material to be machined, often a metal or plastic block, is securely mounted onto the CNC milling machine’s worktable or fixture using clamps or vises. It’s crucial to ensure that the material is properly aligned and secured to prevent any movement during machining.

With everything set up, the CNC milling machine begins the machining process according to the programmed toolpaths. The cutting tools move along the specified paths, removing material from the workpiece to create the desired shape and features..

Once the primary machining operations are complete, secondary processes such as deburring, surface finishing, and hole tapping may be performed to refine the part’s appearance and functionality.

Before the parts are ready for delivery, a final inspection is conducted to ensure they meet the customer’s requirements and quality standards. Once approved, the parts are carefully packaged to protect them during transit and delivered to the customer, ready for use in their intended application.

| Standard | Metal Part | Plastic Part |

|---|---|---|

| Max. Part Size | 1600 x 1400 x 800 mm | 1600 x 1400 x 800 mm |

| Min. Part Size | 1 x 1 mm | 1 x 1 mm |

| Min. Feature Sizes | φ 0.20 mm | φ 0.20 mm |

| (φ 0.00197 in.) | (φ 0.00197 in.) | |

| Standard Tolerances | ISO 2768-f | ISO 2768-m |

| Part Tolerance | 0.01 mm(0.0007 in.) | 0.01 mm(0.002in.) |

| Hole/Shaft Tolerance | 0.01 mm(0.0008 in.) | 0.01 mm(0.0008 in.) |

| Edge Condition | The corners of the item will be taken off in the form of a chamfer or radius, as outlined on the drawing. The size of the resulting chamfer or radius must also be specified. | |

| Threads and Tapped Holes | Diameter: 1.5 – 5 mm; Depth: 3*Diameter | Diameter: 1.5 – 5 mm; Depth: 3*Diameter |

| Diameter: 5+ mm; | Diameter: 5+ mm; | |

| Depth: 4 – 6*Diameter | Depth: 4 – 6*Diameter | |

| Text Engraving | Min. Width: 0.5 mm | Min. Width: 0.5 mm |

| Min. Depth: 0.1 mm | Min. Depth: 0.1 mm | |

| Lead Time | 3 Days | 3 Days |

| Method | Description |

|---|---|

| Anodizing | Electrochemical oxidation of metals or alloys. Form oxide film on aluminum. |

| Sanding & Polishing | A surface modification technology to obtain specific surface roughness. |

| Bead Spray + Anodizing | Form a dense oxide film on surface to increase corrosion resistance. |

| Water Plating | Equip different special water plating solutions according to various needs. |

| Vapour Polishing | Steaming and fumigation treatment improve the product’s transparency. |

| Passivation | Transform the metal surface into a state not easy to be oxidized. |

| Hard Anodizing | Improve many properties of deformed and die-casting aluminum alloy parts. |

| Powder Coating | A coating film will be formed on the surface to achieve the particle effect |

| Painting | It is water & oil resistant and dry quickly, used to paint cars, wood, etc. |

| Chrome Plating | Metal chromium is easy to form a very thin passivation film on the surface. |

| Electrophoresis | Using charged particles’ different moving speeds in to separate. |

| Electropolishing | Electrolyzes under specific conditions to make a mirror luster appearance. |

| Sandblasting | Roughening the surface by using the impact of high-speed sand flow. |

| Heat Treatment | Change the chemical composition and structure in the solid state. |

| Brushed | Form lines on surface by grinding to reflect the texture of metal. |

| Electroplate | Plating a thin layer of other metals or alloys on the surface of materials. |

| Etching | Usually referred to as etching, also known as photochemical etching, it refers to removing the protective film from the area to be etched through exposure plate making and development, and then contacting the chemical solution during etching to achieve the effect of dissolving corrosion and forming concave and convex or hollow molding effects. |

Feel free to Contact Us, provide the best solution for your custom project.

Offering cost-effective solutions without compromising on quality.

CNC machining is also called computer numerical control machining. We do the following machining services: milling, turning, drilling, threading, tapping, EDM and wire EDM, custom surface finishing, prototype machining, low volume or one-off part machine run, modification of an existing part, material sourcing assistance, limited material warehousing and parts dispatching.

From prototype to production, from 1 to 10,000 pieces, we offer fast turnaround CNC machining of your custom metal and plastic parts with as fast as 3-day delivery.

Reliable CNC Machining has a 25,000-square-foot CNC machining shop. With 50+ skilled employees and 15 high-performance CNC machines, maintain 24/7 operations and can deliver over 200 machining projects and 15,000+ machined parts per month in our CNC machining centers.

Our engineering and sales teams will provide one-on-one quote support for your project. Typically, for similar parts, CNC lathes cost 15% less to machine than standard 3-axis CNC milling. In contrast, the cost of 5-axis machining increases, continuous 5-axis CNC milling typically costs over 20% more than an indexed 5-axis machine (also referred to as 3+2 milling), and about double that of a standard 3-axis mill. To achieve the most cost-effective CNC machined parts, larger production runs are recommended to spread the cost of machine setup.

Maximum Dimensions (3-axis milling): 1600×1400×800 (mm).

Maximum Dimensions (5-axis milling): 450×700×400 (mm), Worktable Diameter Φ400 mm.

Once the machining process is complete, the CNC parts surface will have slight visible tool marks, called “as-machined” or “as-milled” surface finish. Machined surface roughness (Ra) is standardized at 1.6-3.2 μm, and surface finish requirements can be increased to 0.8-1.6 μm or higher at 0.2-0.8 μm, however, this will require more operating time and higher costs.

“Reliable CNC Machining” is a brand of SINO-TOOLS INDUSTRIAL CO., LTD © 2025 All Rights Reserved