Optimalisatie van CNC-bewerkingstoleranties voor kostenefficiëntie en precisie

Understanding Tolerances in CNC Machining Tolerances in CNC machining refer to the permissible limits of variation in a physical dimension or measured value of a manufactured part. They play a crucial role in ensuring that parts consistently fit and function as intended within the assembly. In essence, tolerances dictate how much deviation from a nominal […]

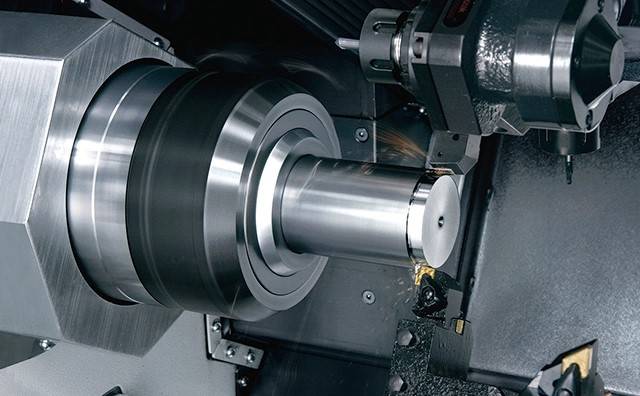

Verbetering van de oppervlakteafwerking van auto-onderdelen bewerkt door numerieke besturing

Optimize cutting parameters Reasonable selection of cutting speed: Cutting speed has a significant impact on surface roughness. Within a certain range, increasing the cutting speed can reduce the deformation of the chip and lower the cutting force, thereby reducing the friction and compression between the tool and the workpiece, which is conducive to improving the […]

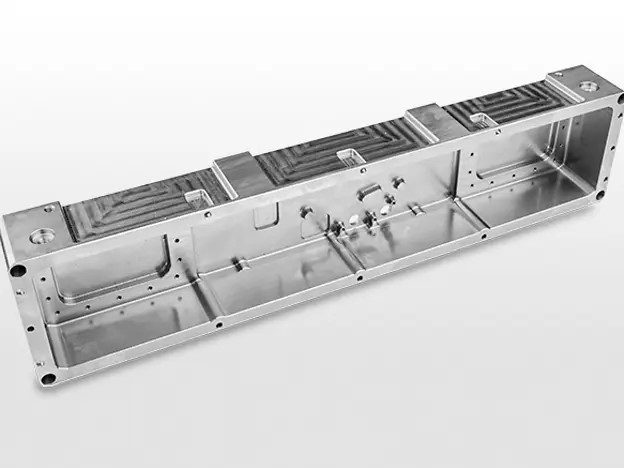

Methoden voor het verbeteren van de dimensionale nauwkeurigheid van CNC-bewerking van auto-onderdelen

The methods to improve the dimensional accuracy of CNC machining of automotive parts can be approached from multiple aspects such as equipment, process, programming, tools, and environment. The following is a detailed introduction: In terms of equipment Equipment accuracy calibration: Regularly calibrate the accuracy of CNC machine tools, including geometric accuracy, transmission accuracy and positioning […]