Techniken zur Verbesserung der Rundheitsgenauigkeit in CNC-Bearbeitungsdiensten

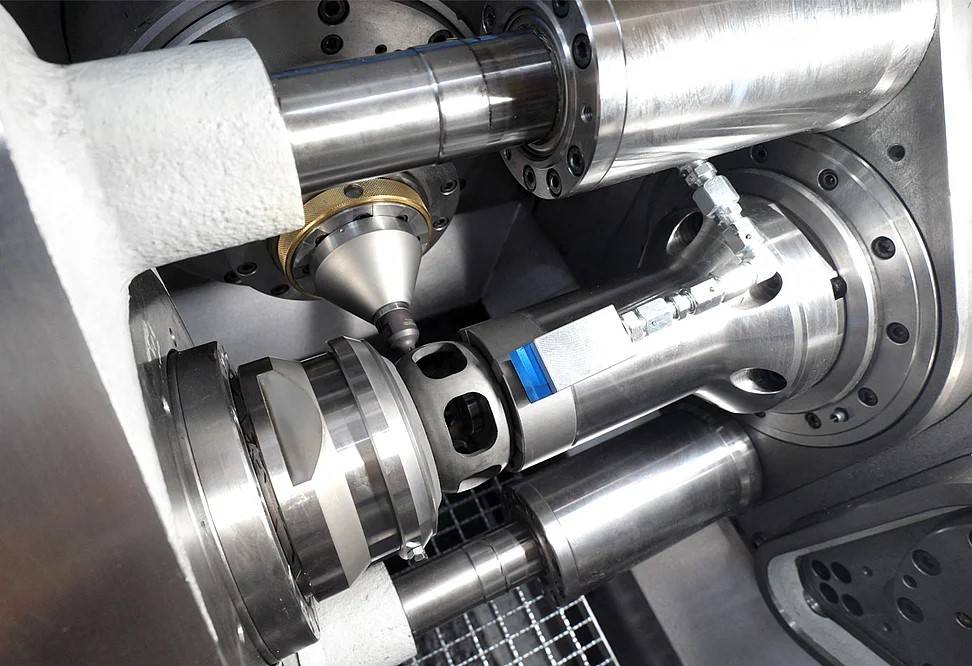

Advanced Techniques for Improving Roundness Accuracy in CNC Machining Services Precision Tool Selection and Geometry Optimization The choice of cutting tools significantly impacts roundness accuracy, particularly in high-precision applications like hydraulic cylinder bores or aerospace bearing journals. For turning operations on hardened steel, carbide inserts with polished rake faces reduce friction-induced tool deflection, maintaining consistent […]

Verbesserung der Oberflächenrauheit in CNC-Bearbeitungsdiensten

Effective Strategies for Enhancing Surface Roughness in CNC Machining Services Optimized Cutting Parameter Selection Adjusting spindle speed, feed rate, and depth of cut directly impacts surface finish quality. For high-speed milling of aluminum alloys, increasing spindle speed to 12,000–20,000 RPM while reducing feed per tooth to 0.05–0.1 mm minimizes chip formation size, creating smoother surfaces […]