Principles for setting cutting parameters in numerical control programming

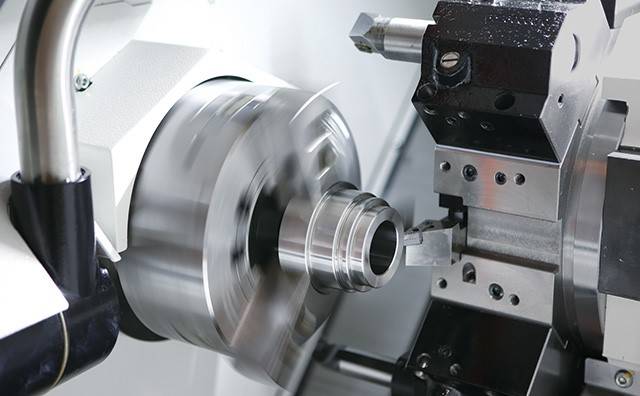

Fundamental Principles for Setting Cutting Parameters in CNC Programming Material-Specific Parameter Selection The mechanical properties of workpiece materials directly influence cutting speed, feed rate, and depth of cut decisions. For ductile metals like aluminum alloys, higher cutting speeds (1,200-3,000 SFM) prevent built-up edge formation while maintaining surface integrity. Conversely, hardened steels require slower speeds (80-200 […]

Analysis of Numerical Control Programming Simulation Methods

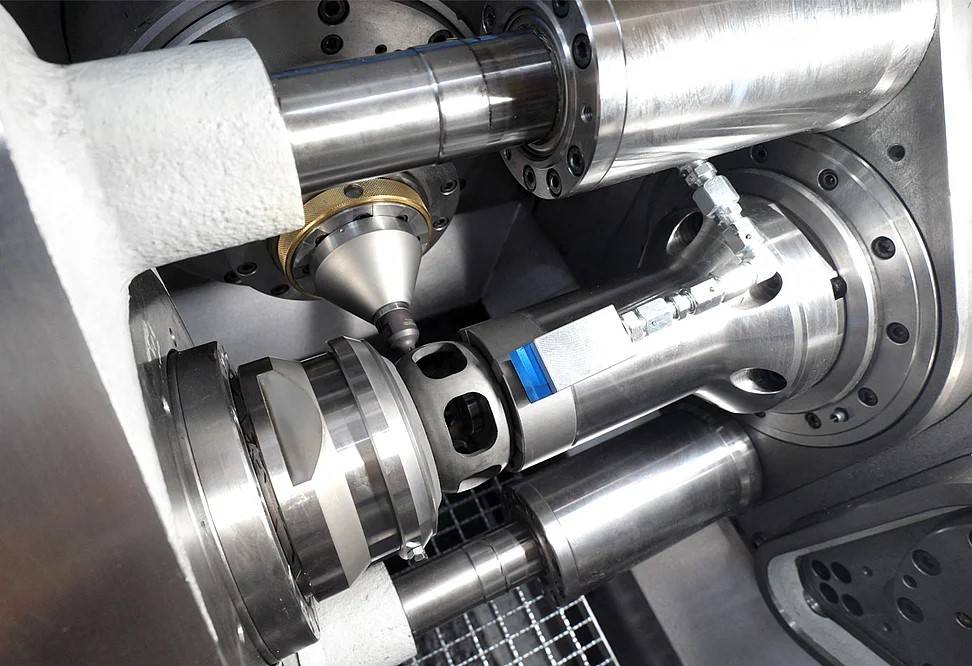

Key Technologies Behind CNC Programming Simulation Virtual Machine Tool Modeling Modern simulation systems replicate physical CNC machines through three-dimensional geometric modeling and kinematic algorithms. This involves constructing digital twins that mirror real-world machine structures, including linear axes, rotary tables, and spindle systems. For example, when simulating five-axis machining centers, the software calculates the inverse kinematics […]