Optimizing Material Selection for Enhanced Machinability in CNC Aluminum Machining

Understanding Machinability and Its Importance Machinability is a critical concept in the field of CNC machining, referring to a material’s ability to be machined effectively and efficiently. It encompasses various characteristics, such as the ease with which a material can be cut, shaped, or finished using machining tools. The significance of machinability cannot be overstated, […]

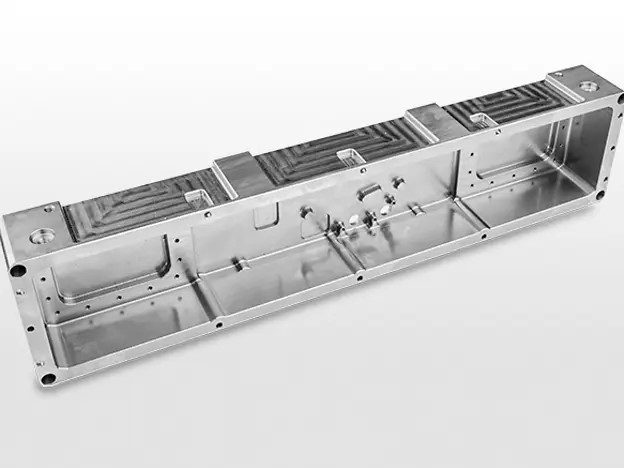

Flatness control measures for CNC machining of automotive parts

Preparatory measures before processing Equipment accuracy verification The accuracy of CNC machine tools is one of the key factors affecting the flatness of parts. Before processing, it is necessary to verify various precision indicators of the machine tool, such as the flatness of the worktable, the rotational accuracy of the spindle, and the straightness of […]

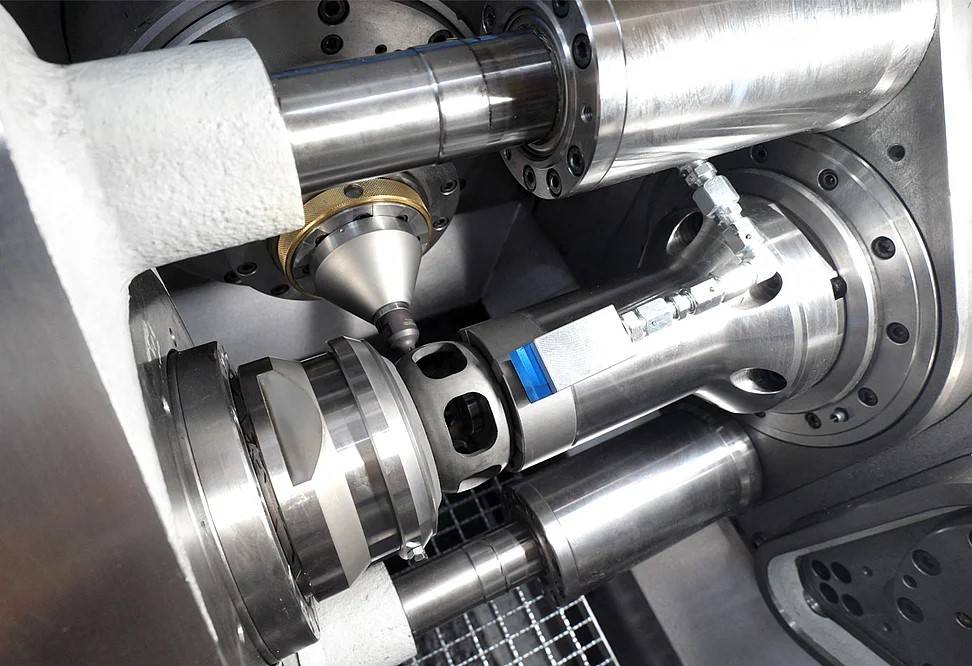

Parallelism guarantee for CNC machining of automotive parts

To ensure the parallelism of CNC machining of automotive parts, efforts can be made from aspects such as processing equipment, process methods, clamping methods, inspection and adjustment: In terms of processing equipment Equipment precision guarantee: The precision of the processing equipment needs to be one to two grades higher than the precision required by the […]